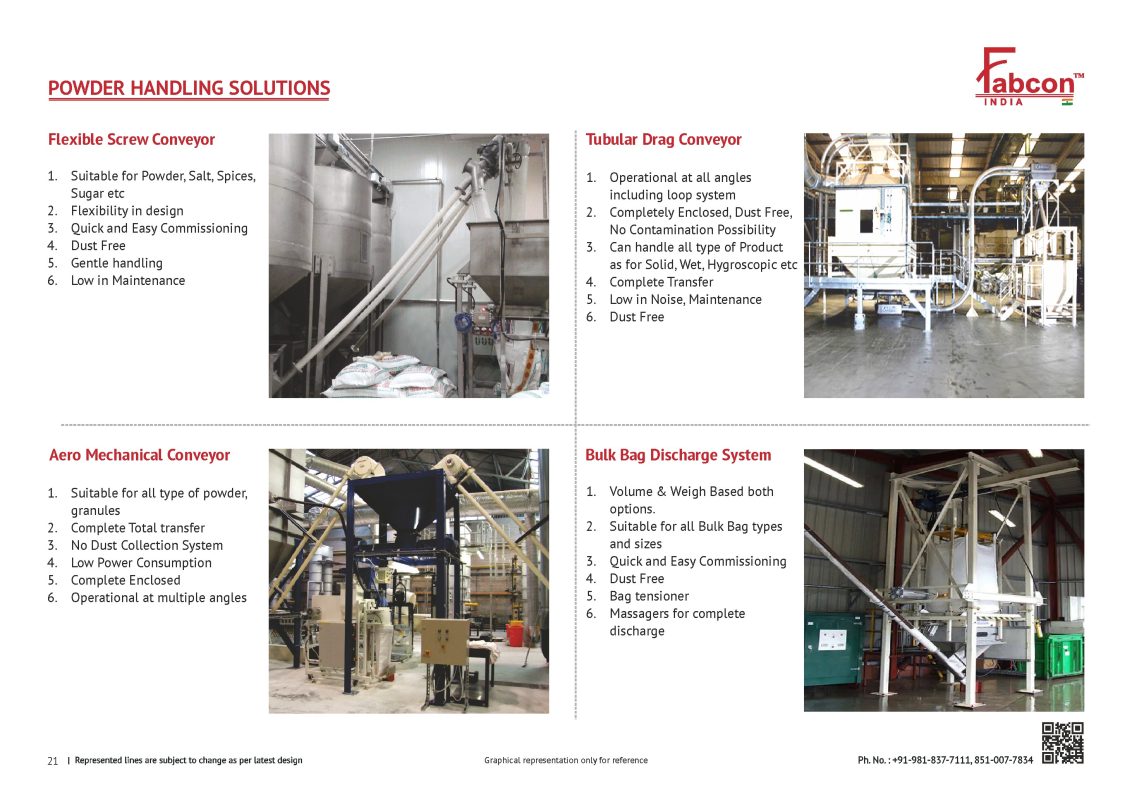

Powder Handling

In the food industry, powder handling solutions are essential for efficiently processing and managing various powdered ingredients. These solutions help with tasks such as mixing, blending, conveying, dosing, and packaging of powders. Here are some different kinds of powder handling solutions that Fabcon India offers:

Flexible Screw Conveyor: The flexible screw conveyor operates by rotating the auger inside the tube. As the auger turns, it creates a spiral motion that pushes materials along the length of the conveyor. The flexible design of the auger allows it to flex and bend within the tube, enabling the conveyor to navigate around obstacles and follow various paths.

Benefits of Our Flexible Screw Conveyors:

1. Versatility: Flexible screw conveyors can be easily adapted to fit into tight spaces or navigate complex routes, making them suitable for challenging plant layouts.

2. Gentle Handling: The spiral motion of the auger ensures gentle handling of materials, minimizing breakage and degradation.

3. Low Maintenance: The uncomplicated design with few moving parts reduces maintenance needs and downtime.

4. Quick Clean-Out: The removable auger and easy-to-access components facilitate fast and efficient cleaning and changeovers.

5. Cost-Effective: Flexible screw conveyors are often more affordable than other conveying solutions, offering a cost-effective method for material transport.

6. Diverse Applications: These conveyors can handle a wide range of materials, from fine powders to larger particles, making them versatile for various industries.

- Aeromechanical conveyors: feature a circular conveyor tube with specially designed discs spaced evenly along the length. These discs are attached to a continuous wire rope or chain that travels around the conveyor circuit. As the discs move through the tube, they pick up and carry the material within the spaces between them.

Benefits:

- Gentle Material Handling: The enclosed tube and gentle conveying action minimize product degradation and maintain the integrity of fragile or abrasive materials.

- High Throughput: Aeromechanical conveyors can handle large volumes of materials, making them suitable for high-capacity applications.

- Dust Containment: The enclosed system prevents dust and spills, ensuring a cleaner and safer working environment.

- Versatility: These conveyors can transport materials horizontally, vertically, or at various angles, adapting to diverse plant layouts.

- Minimal Maintenance: The simple design and limited moving parts reduce maintenance requirements, leading to lower operational costs.

- Flexible Configurations: Aeromechanical conveyors can accommodate multiple inlets and outlets, allowing for flexible material transfer between various points.

- Tubular Drag Conveyor: The tubular drag conveyor is a robust and versatile solution designed for the seamless and gentle handling of a wide range of bulk materials.

Key Features and Benefits:

- Material Integrity: The enclosed tube design ensures that materials are transported with minimal degradation, making it ideal for fragile or sensitive products.

- Versatile Material Handling: Tubular drag conveyors can transport a diverse array of materials, including powders, granules, pellets, and even wet or sticky substances.

- Low Energy Consumption: Thanks to its efficient chain-driven mechanism, the tubular drag conveyor offers energy savings and reduced operational costs.

- Customizable Layouts: The conveyor’s flexibility allows it to navigate various paths, including horizontal, vertical, and inclined routes, adapting to facility layouts.

- Dust and Contamination Control: The enclosed design minimizes dust emissions and prevents contamination, enhancing worker safety and product quality.

- Multiple Inlets and Outlets: Tubular drag conveyors can accommodate multiple inlets and outlets, enabling efficient material transfer between different points.

- Easy Maintenance: The straightforward design and minimal moving parts contribute to reduced maintenance requirements and enhanced uptime.

- Bulk Bag Discharge System: Bulk bag discharge systems, also known as bulk bag unloaders or bulk bag dischargers, are specialized equipment designed to facilitate the efficient and controlled unloading of bulk bags.

Features:

- Safe and Controlled Unloading: Bulk bag discharge systems ensure controlled material flow, preventing spills and minimizing operator exposure to dust.

- Dust Containment: These systems incorporate dust collection mechanisms to capture and contain airborne particles, maintaining a clean and safe working environment.

- Hygienic Design: Many bulk bag discharge systems are designed with hygiene in mind, making them suitable for industries with strict sanitation requirements, such as food and pharmaceuticals.

- Material Conditioning: Some systems include features to agitate or massage the bulk bag, promoting material flow and preventing clogs.

- Versatile Applications: Bulk bag discharge systems can handle a wide variety of materials, from fine powders to larger granules.

- Integration with Conveyors and Processing Equipment: These systems can be integrated seamlessly into existing conveying and processing lines, streamlining material transfer.

- Customization: Bulk bag discharge systems come in various configurations and sizes to accommodate different bag sizes, material properties, and processing needs.

Fabcon India has earned its reputation as a leader in the food processing industry by consistently delivering innovative solutions, customized expertise, and unwavering support to their clients. From start-ups to industrial brands, food processors around the globe trust us to help them achieve operational excellence, enhance product quality, and drive business growth. If you want to further explore our range of powder handling solutions, please connect with us soon.