Vibratory Controlled Feeding System

A system that vibrates components or materials along a track or trough is known as a vibratory-controlled feeding system. The system comprises a track or trough, a control unit, and a vibratory feeder. A tray or bowl that vibrates at a high frequency makes up the vibratory feeder.

The components or materials move down the track or trough as a result of the vibration. To regulate the flow rate and guarantee that the components or materials are fed at a constant pace, the vibration’s amplitude and frequency can be changed.

In manufacturing and assembly processes, vibratory-controlled feeding systems are frequently used to feed components to a production line. In general, vibratory-controlled feeding systems are very effective, and they may be tailored to fit the unique requirements of a variety of applications.

Products can flow through manufacturing more rapidly when conveyors are used, which helps to satisfy increased demand. Moreover, it is necessary to carry out the tasks of storing, sorting, orientating, assigning, placing, and inserting promptly, safely, and without causing any harm to the goods.

Vibratory-controlled feeding systems have applications across the food industry. Such as:

- Chips

- Wafers

- Extruded snacks

- Cereals

- Slurry coated snacks

- Low-bulk density food products

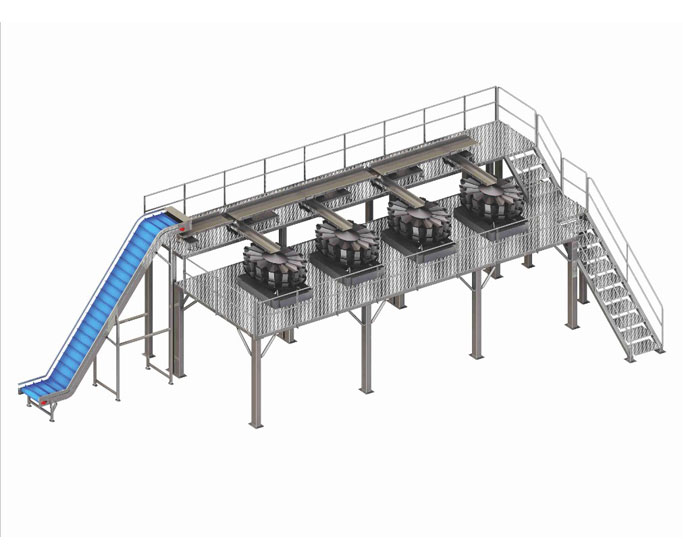

Our vibratory-controlled feeding system

You can obtain the highest level of conveying automation, assured lifespan, controlled or metric feeding, and sanitary operation by adding vibratory-feeding systems to the food processing lines.

Our vibratory-controlled feeding system offers the following features:

- Continuous feed for the upstream line is provided by the electromagnetic vibratory feeder

- 100% sanitary rigid construction

- Offers perfect integration while enhancing material’s durability & manufacturing costs.

- Adaptable to the need for item distribution and as per desired conveying requirements

- Emphasis towards food safety and absence of residual regions

- Durable 2.5 mm SS Sheet construction for the tray

- Minimum breakage and delicate product handling

- Dedication to the highest standards of excellence

- GMP-compliant design and fully hygienic

Benefits:

- Provides delicate, intellectual and reliable product transfer system

- Maximized product conveying efficiency without breaking the product and very minimal product coating loss

- Helps in conveying difficult to handle product

- The aisle sides provide access for installation and cleaning

- Hygiene is driven to ensure food safety from contamination and reduces labor costs

- No moving parts

- Have multiple drops

- 100% sanitary rigid construction

- Large carrying capacity

- Noiseless system operation, less vibration and dynamic load for a lighter support apparatus

- It is fully modular

We can provide you with the professional guidance in addition to the real-world manufacturing-related solutions you need.